Repairs

When we sell restored or fully refurbished Aibo's we offer our 12 month no quibble guarantee - this document will outline what it covers (and what it doesn't)

We guarantee that for a 12 month period we will repair any faults that occur from normal use of the associated product.

This excludes any faults that occur from damage or misuse - we don't cover any consequential loss of any kind for any reason so if your Aibo was due to be in a film or advert we won't cover any loss associated with anything like this.

Other than that we don't put in place crazy restrictions but we do specify that the shipping to us is to be covered by the buyer - this is the same as any normal manufacturer or repairer.

Providing we can identify that the fault was not caused by misuse we will repair and return the item to the customer (in the UK) for free - if you are overseas you will be responsible for return shipping.

If however the fault is found to be related to misuse and/or damage then the customer will be charged a diagnostic fee (£75) and we will offer a quote for the repairs.

Should you decline this quote you will still be liable for the diagnostics fee of £75 and the return shipping costs before we will return the item to you.

** Battery re cell procedures do not carry a 12 month guarantee - they are covered by a standard 3 month guarantee which covers defective parts that have been used during the repair procedure**

**The circuitry in older Aibo packs is as much as 21 years old and as such our guarantee does not cover the original electronics within the pack - it is limited to the cells themselves and any defects in our craftsmanship**

**Under normal use the new cells will perform as good as or better than the original ones that Sony put in when they were new and we have packs in our own Aibo's that have been running for many years without issue**

All Errors and Omissions are excepted.

Yes you saw that for real, I can and will repair most faults to the pcb contained within the battery of all Aibo models.

One of the biggest killers of Aibo batteries is lack of use, yes this may sound odd but when the cells drop below a certain value a protection circuit kicks in and then this prevents the cells form being charged (as it could overload the charging circuit and/or damage the battery).

This protection circuit is necessary because of the way lithium ion batteries are charged. Their initial charge period is called constant current where the current is allowed to ramp up to the max available by the charging circuit.

After this initial flood charge period the battery will achieve it's potential max voltage (8.4volts for 7.4 volt packs) the charger then switches to constant voltage charging mode where the voltage is held at 8.4 volts (for 7.4 volt packs) and the current is slowly reduced by the battery demanding less and less from the charging circuit.

Eventually this current will drop to the float level which is the value required to keep the pack topped up but not over charge it and cause overheating.

Aibo batteries have this charger design and like most lithium ion battery packs they are of the smart battery design, this has some of the protection circuitry within the battery itself and is part of the problem that Li-ioN smart batteries suffer from as a whole.

Once that pack voltage drops below a certain threshold it's days are numbered.

What this then means is that the voltage inside can only drop as the cells gradually leak voltage unless charged to a very specific storage charge, flaws in the design of the circuit meant that even new unused batteries become useless after prolonged periods of storage.

This then created that catch 22 situation where the battery needed charging but the battery refused to let the system charge it - effectively disabling itself forever (in most cases).

The internal cells then continue to reduce in voltage until they get to a stage that they will never recover, even if they are charged outside of their internal charging circuitry by opening the case. This is the case for the vast majority of original Aibo 110/111/210/220/300 and 7 series batteries and re-celling is the only option.

We can replace the cells in all models of battery and when re-celled the batteries will be of a higher capacity than they were when manufactured as the batteries available today have higher energy densities than were available back then. However this does not necessarily mean your AIbo will run twice as long with a 4ah cell structure as opposed to a 2ah one.

Lithium Ion cells suffer what is known as sagging - the drain on the pack pulls the voltage down - Aibo sees this and will switch off towards the end of the pack charge - often you can switch them back on and they will run another 20 minutes or so.

In tests (and reported by our customers) run times on 210 batteries that we have re celled have run for well over 2 hours and as long as 3 hours in active use.

When it comes to repairing the pcb's within we reserve the right to reject any repairs that are clearly beyond economic repair because a budding diy enthusiast has fried it big time.

As seen in the image below - storage for extended periods can cause the cells within to leak and corrode.

We use the same spot welding techniques used by the original pack manufacturer and maintain all the correct insulation methods and cable and cell placement - we don't cut any corners and all safety features remain intact.

The pack control circuitry gets reprogrammed to allow it to correctly record the higher capacity of the new cells - all charge counters are also reset.

After re cell / repair has been completed your batteries will look like the image below (ERA201B - ERS210/220 Battery) inside :-

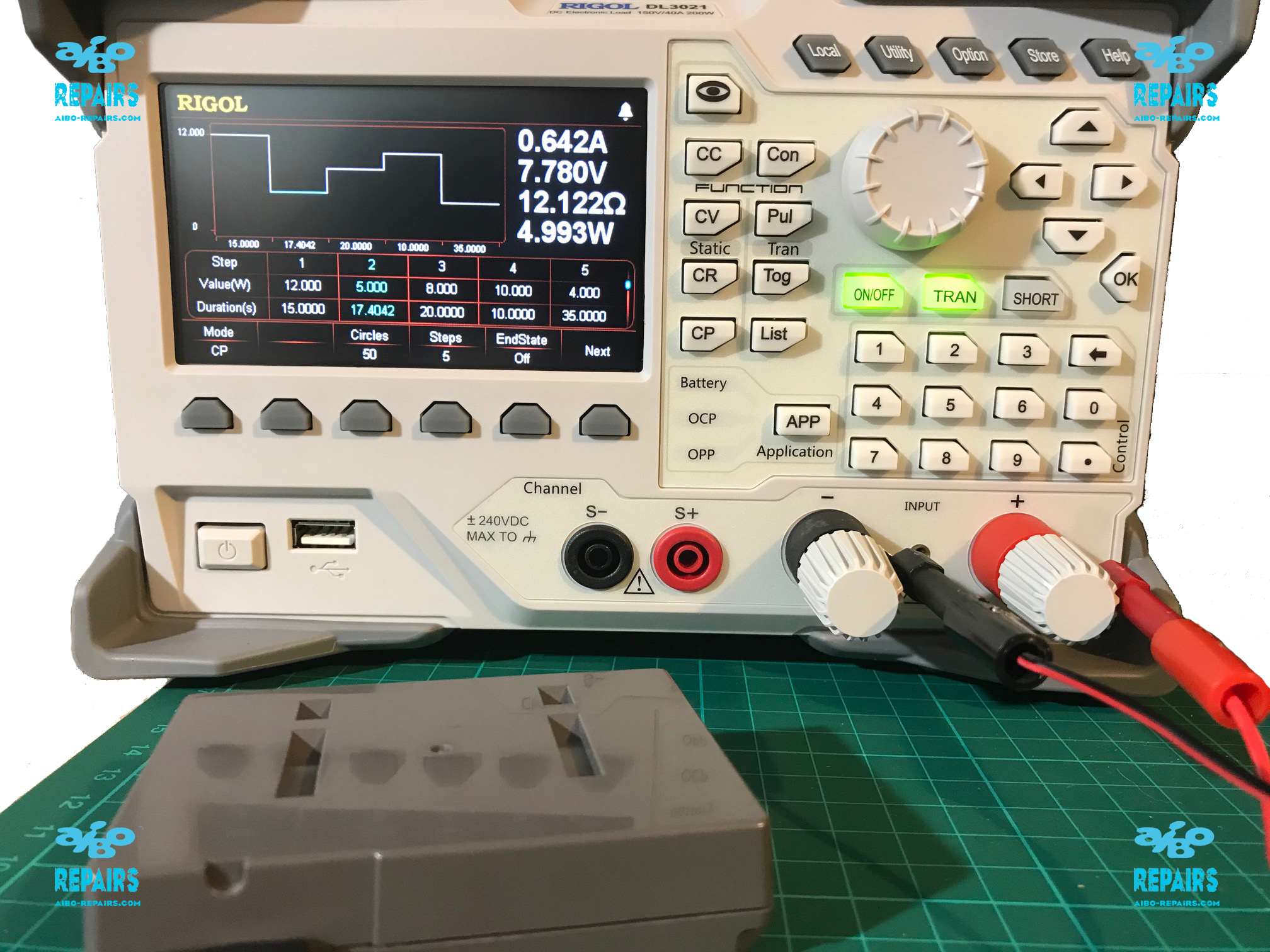

All our repaired / re celled batteries undergo rigorous testing prior to being shipped using our state of the art DC load testing kit as shown below:-

*******ANNOUNCEMENT - LEG/HIP/NECK JITTERS*******

Today is another big news day (20th April 2021)

-----------------------------

We can now source on an ongoing basis replacement original fitment sensors for all Aibo models from the 210 upwards

These are in addition to our upgraded retrofit sensors so we can offer the choice to owners to go new original or new retrofit (where available/applicable)

-----------------------

We can also fit new original fitment paw pad touch sensors to enable your Aibo to detect being picked up etc.

Some images of the new parts we have sourced are below:-

The primary reason for replacing sensors is to prevent constantly needing to clean your existing sensors - the reason they need cleaning so often was discovered by us to be deep scoring on a microscopic level after years of normal use - the image below show just how deep that scoring goes - sometimes it is all the way through the resistive layer causing your Aibo to force a movement to try to determine at what position the servo is in - this is what causes the characteristic jitters that we all fear.

In even more good news we can now also replace the sensor discs within the aibo's servo motors found in the heads of 210's and we can also replace the flexi ribbons if they have been damaged. This is thanks to Chris at the Aibo Clinic who has pioneered the replacements.

No more repairs needed - we can simply replace them. - The new flexi's and their sensor pcbs are shown below:-

******STOP PRESS - THE CURE FOR AIBO LEG JITTERS - ERS-210 ~ ERS-7 (INC ALL MODELS IN BETWEEN)******

For clarity - we can now replace or upgrade the leg pots on all models between ERS-210 and ERS-7 (inclusive)

The information below is retained only for historic purpose due to the development above.

Ok so elsewhere I have covered the other "Syndromes" of the ill-fated Aibo family (well most the ERS-210 up to now) and yet another common problem persists within the Aibo gene pool.

This is the well known (and far reaching) leg and or head tremors. The compact nature of the Aibo family required many many engineering challenges to be overcome without creating a unit that cost $20,000 and just wouldn't sell, so best efforts were used in the name of an affordable product (well sort of)and a compact unit.

One of these best efforts was to use resistive motor location instead of optical location so a small variable resister is used which changes it's output value based upon where the motor (and it's attached limb) is positioned. This was an elegant design and was well used within the radio controlled model servo industry so it was tried and tested. The significant difference between these two methods of use was that in most cases a radio controlled model would be lucky to last 20 weeks let alone 20 years and as such inherent wear and dirt ingress was bound to come into play.

This wear and dirt ingress exhibits itself as tremors in the Aibo's limbs and can be quite distressing to watch sometimes and is caused by dirt entering the variable resistor component and altering the accuracy of the output it generates, sometimes it is just worn out. This then leaves Aibos servo motors controlling it's limbs unable to detect their exact position and causes the tremors as the motors continually try to correct their position over and over without success.

The resolution for this is first to determine of it's just dirt ingress or if the part is actually worn out and once this has been determined the corrective method is applied with either the unit being cleaned or replaced.

Most Aibo's exhibiting tremors only do so after many years of use and this syndrome is not normally associated with units that have been shelf queens or are new old stock.

Once repaired the units function normally and as yet none of my own pack that have received this repair have ever re exhibited any tremors (except when faced with my Dalmatian). Granted they don't get used as much now as they did in the early days but it usually takes many years for enough dirt to get in there to cause a problem.

By now we all pretty much understand that Aibo is very technically advanced even by todays standards and pretty much broke the mould when it was launched back in 1999. That's a given. Unfortunately all the tech is crammed into a really small place and anyone who owns an older generation camcorder knows full well that it would be unlikely to be still fully functional after 20 years!!.

So why do we expect more from Aibo , well that's mainly because they were never considered a piece of tech or an appliance as such and for the enthusiasts and adult owners they were more part of the family, perhaps more so for any of the few lucky enough to have had parents prepared to spend over $2000 dollars on a gift for them.

Under normal circumstances youthful exuberance and tech didn't mix very well back in the noughties and some Aibo's suffered this fate receiving broken limbs or joints, trips and falls that left them unusable and destined for the cupboard or loft space. Their adult owners often included college or university dwellers too so you can imagine what happened there on an occasional Saturday night. The problem with any breakages on Aibo was two fold, firstly they were just so expensive to repair with Sony and secondly if anyone tried any kind of glue fix it had very little chance of long term success as the glued joint would be under so much stress just in normal use that it would often fail very quickly.

As time went by more and more of these maltreated or misused Aibo's found their way into cupboards and lofts all over the globe as Sony were no longer supporting them and parts were few and far between.

Sadly some Aibo's were just too far gone to be repaired and that left only one fait for them and that was to try to help other slightly more fortunate ones to live again. Yes it's sad but so is death in general and Aibo's are no different from humans in this respect as we all know how successful the human organ donor transplant system has been at saving lives for desperately ill people.

The same goes for Aibo in our eyes and we maintain a very thoughtful process for any Aibo's used for donor parts via our Aibo-Donor-Program at our sister site www.Aibo-Donor-Program.com where we keep previous owners fully updated with the progress of any Aibo's that have been rescued thanks to the generosity of individuals who have donated their faithful friends after their time has come.

We even provide certificates with can be displayed proudly to state that their lost pet lives on in other Aibo's whom without their help may have suffered the same fait.

Obviously using donor parts is our last option and rare to find parts are often re manufactured or even manufactured from scratch using our state of the art CAD systems and 3d printing and small scale manufacturing equipment which allows us to reproduce parts that otherwise couldn't be replaced.

Needless to say we do whatever is possible to keep Aibo going strong and we even provide yearly service plans to keep your techno pals in good running order.

For us Aibo ins't a business, it's an obsession!!